LSB Series Semi-hermetically Water Chilling Unit

Features of the Unit

Highly Effective and Energy-saving

- With PLC and single-chip microcomputer control, this unit can be adjusted automatically to provide multi-stage refrigeration capacity output and realize automatic and dynamic match with refrigeration duty. Therefore, the unit always works effectively and saves energy.

- Due to accurate pipeline design, pipeline resistance loss is minimized, and unit efficiency is enhanced.

Stable and Reliable

- Main parts and components arc famous brand products at home and abroad, so the system works stably and reliably.

- Automatic control system of the unit is controlled by imported programmable logic controller (PLC) or single-chip microcomputer (SCM), and realizes automatic safety protection in case of open phase, ovcr-voltagc, undcr-voltagc, ovcr-currcnt, oil pressure, high pressure, low pressure and electronic motor overloading. With PLC control, the compressor balances operation time automatically, so as to prolong its service life.

- Remote alarm and monitoring interface can be reserved according to requirements.

Compact Structure

- With compact design concept, the unit occupies a small installation area.

- Provide ''modularized'' installation, lessen installation period, reduce pipeline consumables and shorten on-site construction period.

Reduce cost

- Realize automatic control of refrigeration system, and reduce daily operation and management costs.

- Reduce investment cost of equipment and machine room.

- Enhance automatic safety performance; reduce the cost of auxiliary safety equipment.

- Compared with traditional ammonia system, this equipment owns simple system and easy operation, and reduces maintenance cost.

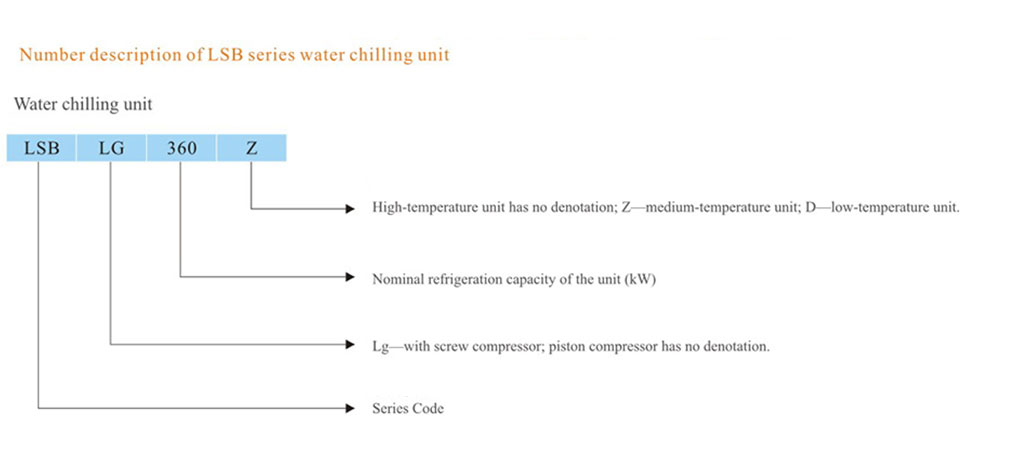

Description:

Description:

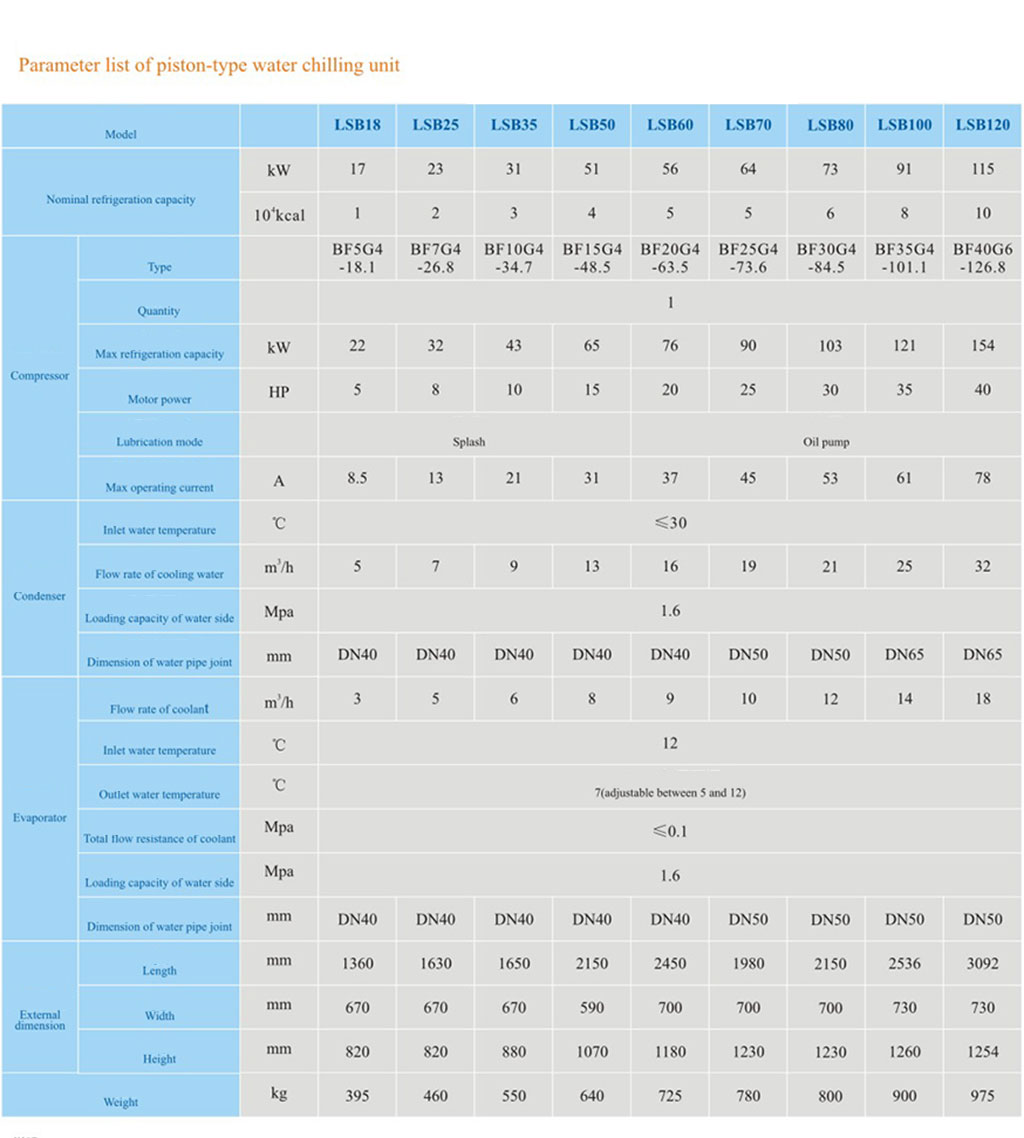

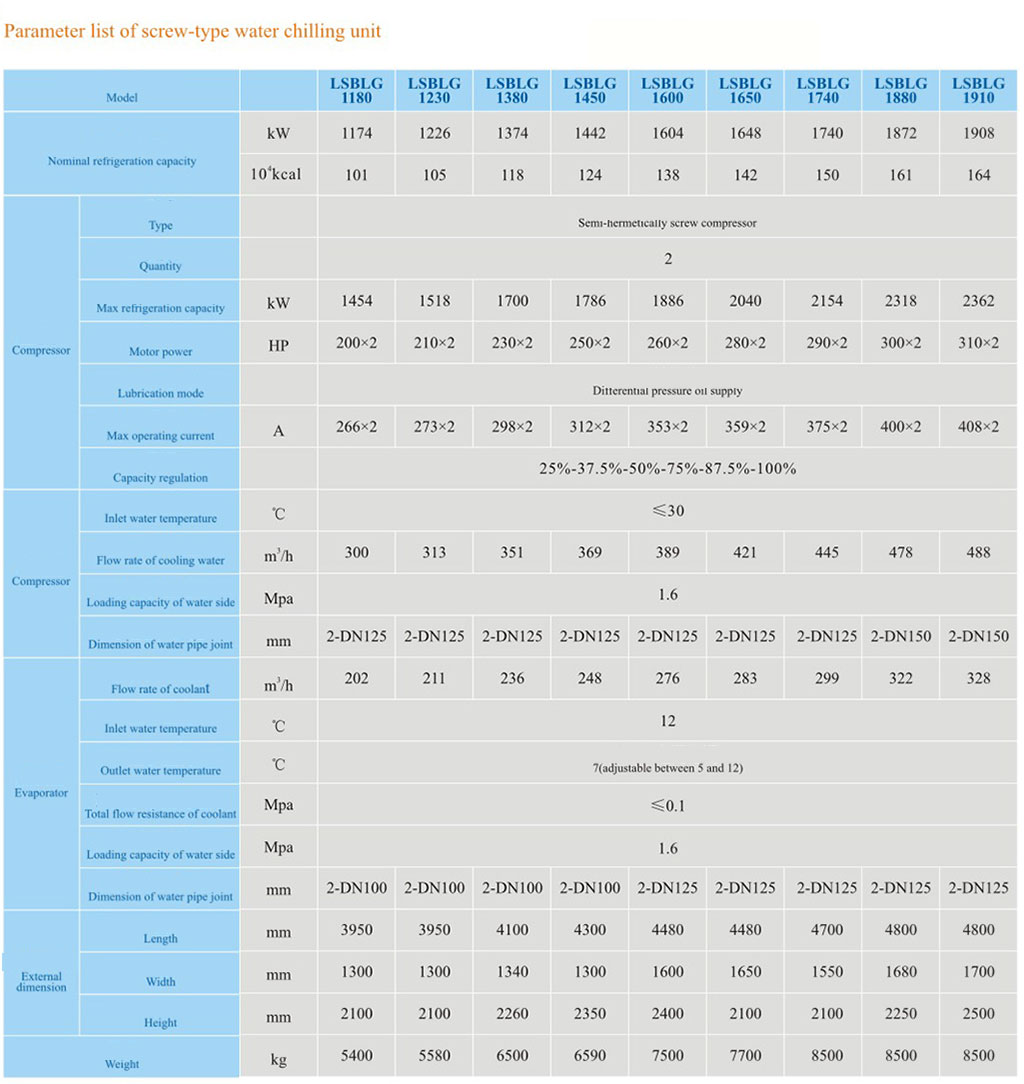

♦Nominal Condition: inlet temperature of coolant is 12'C; outlet temperature of coolant is 7"C. Inlet temperature of cooling water is 30*C; outlet temperature of cooling water is 35"C.

♦Power supply mode: 3P/38OV/5OHz. Allowable voltage fluctuation is ±10%. and allowable interphase voltage difference is ±2%.

♦Above data arc performance parameters of units which refrigerant is R22. For other working media such as R134a and R407C, please contact us.

♦Due to technological improvement, external dimension may be changed and is only for your reference. Please ask us for installation dimensions anytime.

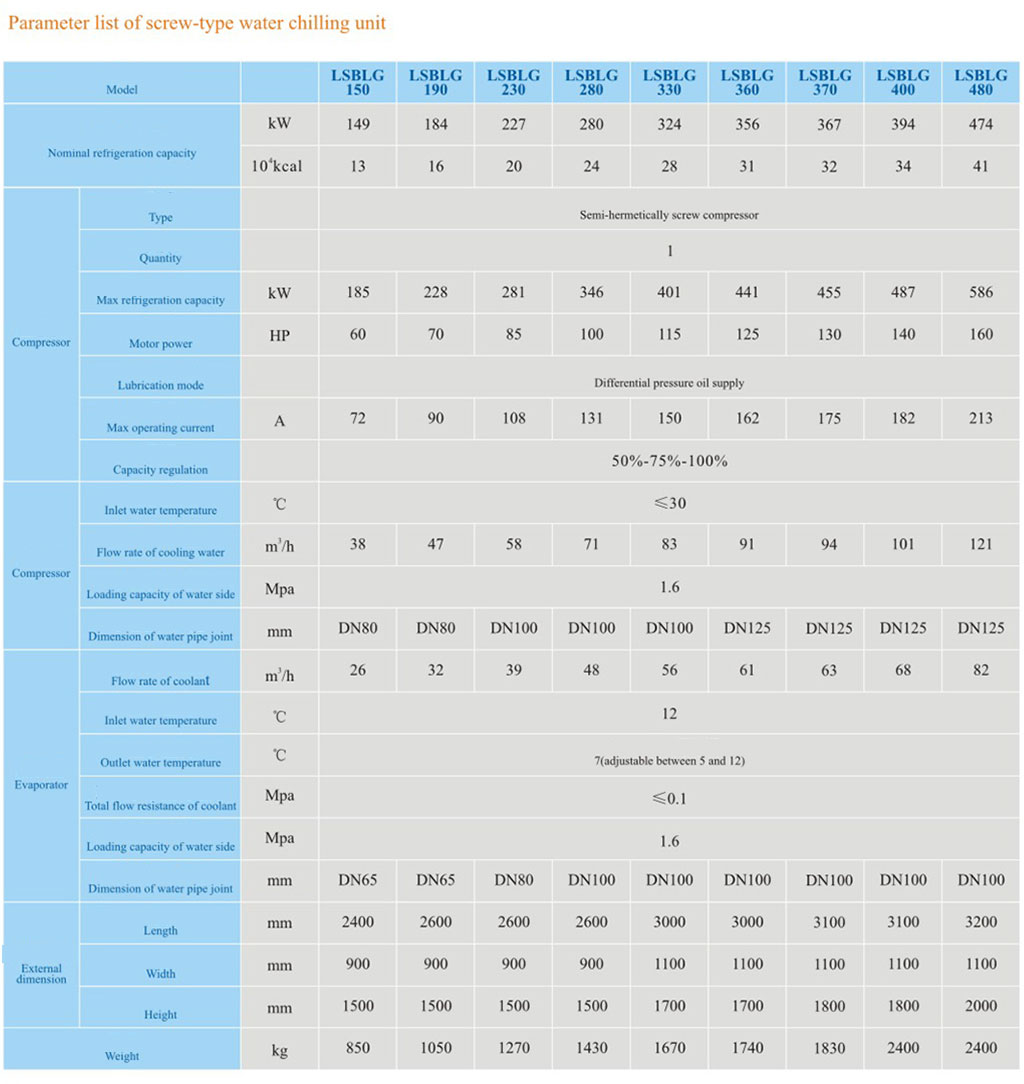

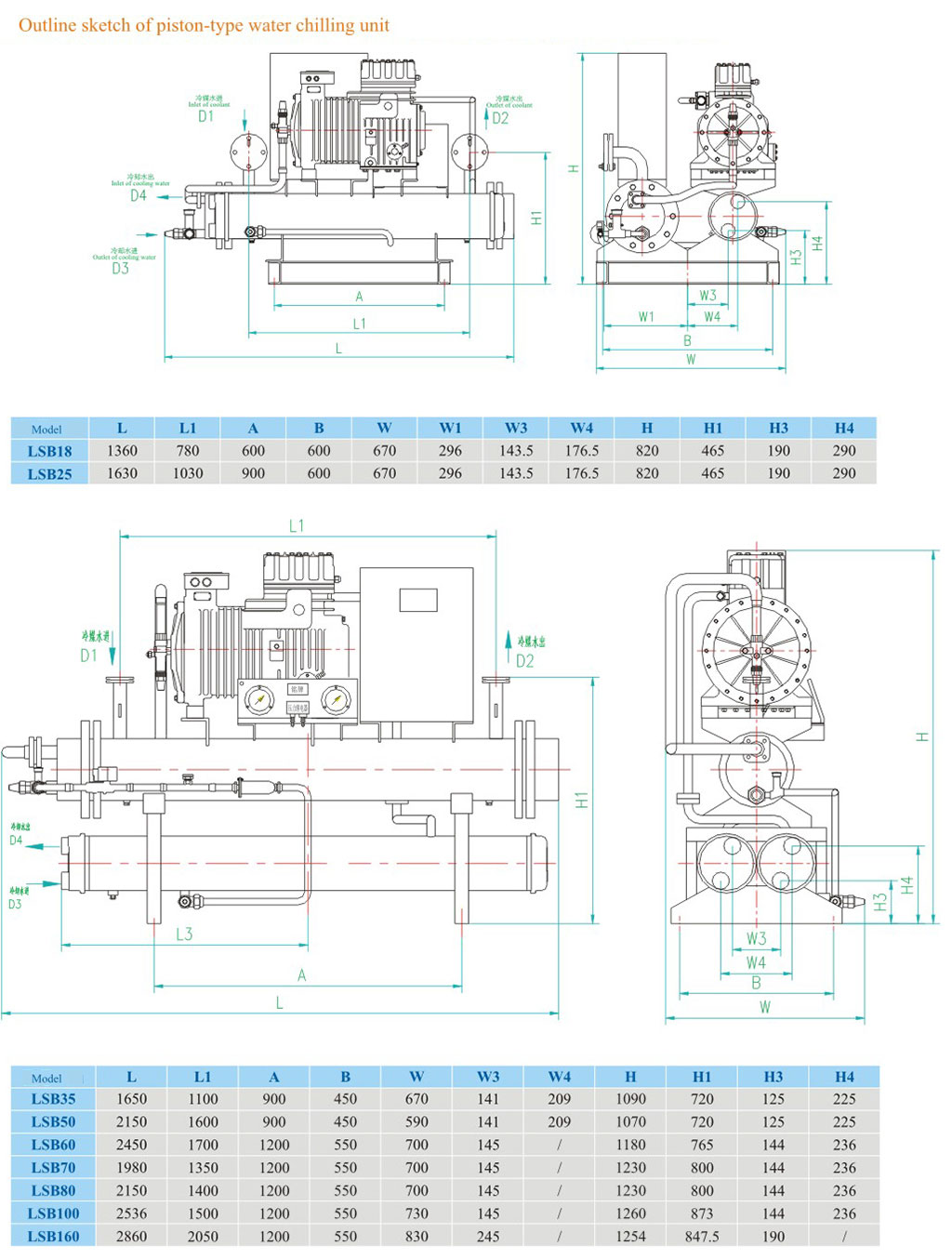

Description:

♦Nominal Condition: inlet temperature of coolant is 12'C; outlet temperature of coolant is 7"C. Inlet temperature of cooling water is 30*C; outlet temperature of cooling water is 35"C.

♦Power supply mode: 3P/38OV/5OHz. Allowable voltage fluctuation is ±10%. and allowable interphase voltage difference is ±2%.

♦Above data arc performance parameters of units which refrigerant is R22. For other working media such as R134a and R407C, please contact us.

♦Due to technological improvement, external dimension may be changed and is only for your reference. Please ask us for installation dimensions anytime.

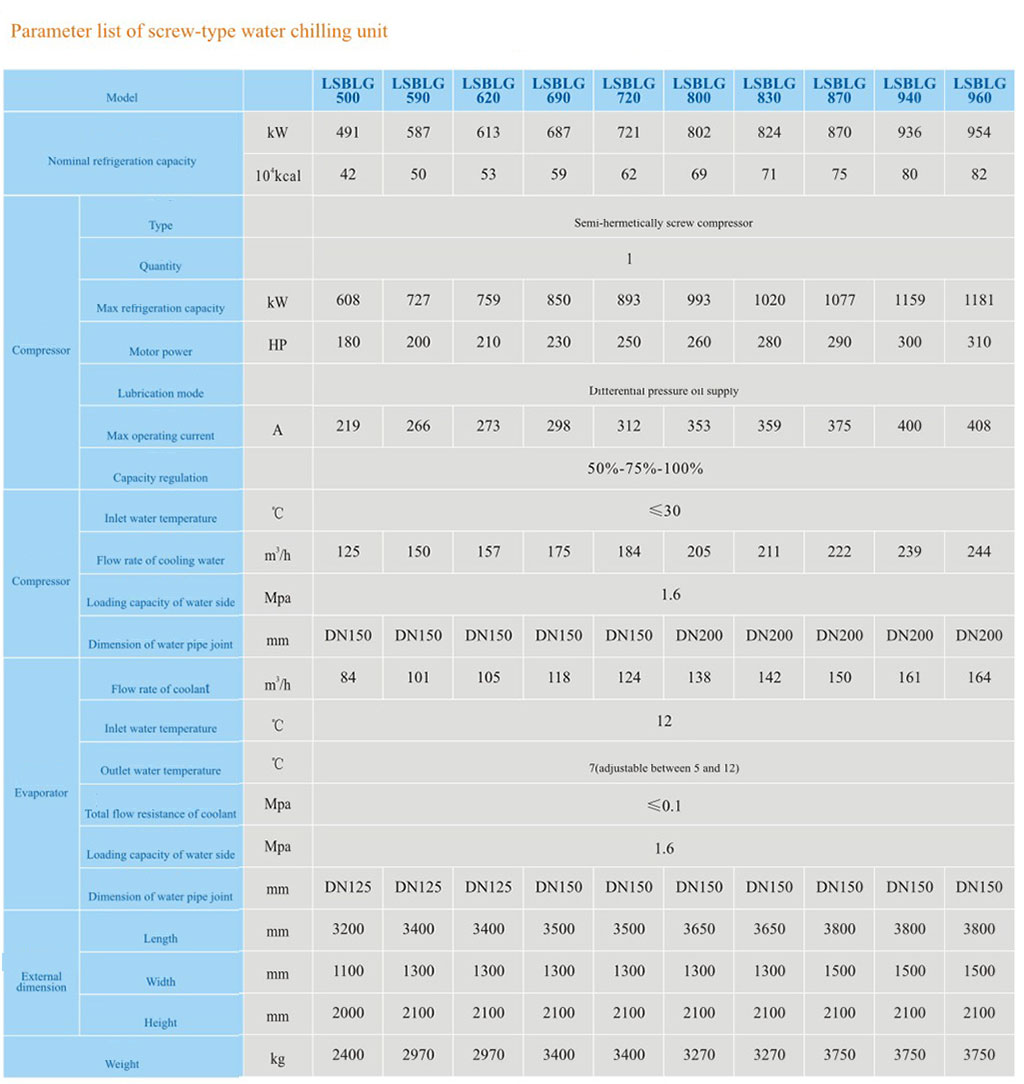

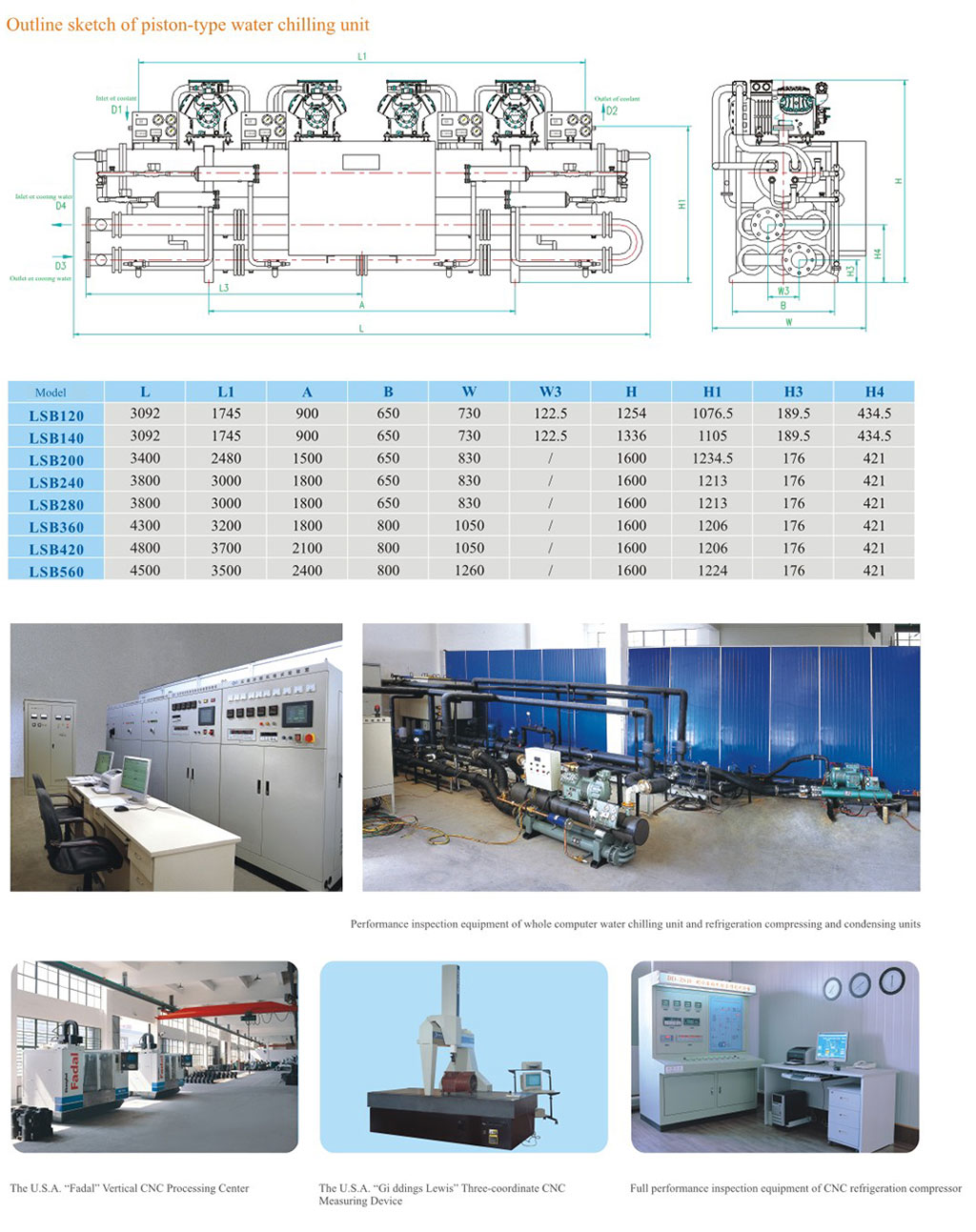

Description:

♦Nominal Condition: inlet temperature of coolant is 12'C; outlet temperature of coolant is 7"C. Inlet temperature of cooling water is 30*C; outlet temperature of cooling water is 35"C.

♦Power supply mode: 3P/38OV/5OHz. Allowable voltage fluctuation is ±10%. and allowable interphase voltage difference is ±2%.

♦Above data arc performance parameters of units which refrigerant is R22. For other working media such as R134a and R407C, please contact us.

♦Due to technological improvement, external dimension may be changed and is only for your reference. Please ask us for installation dimensions anytime.

Description:

♦Nominal Condition: inlet temperature of coolant is 12'C; outlet temperature of coolant is 7"C. Inlet temperature of cooling water is 30*C; outlet temperature of cooling water is 35"C.

♦Power supply mode: 3P/38OV/5OHz. Allowable voltage fluctuation is ±10%. and allowable interphase voltage difference is ±2%.

♦Above data arc performance parameters of units which refrigerant is R22. For other working media such as R134a and R407C, please contact us.

♦Due to technological improvement, external dimension may be changed and is only for your reference. Please ask us for installation dimensions anytime.

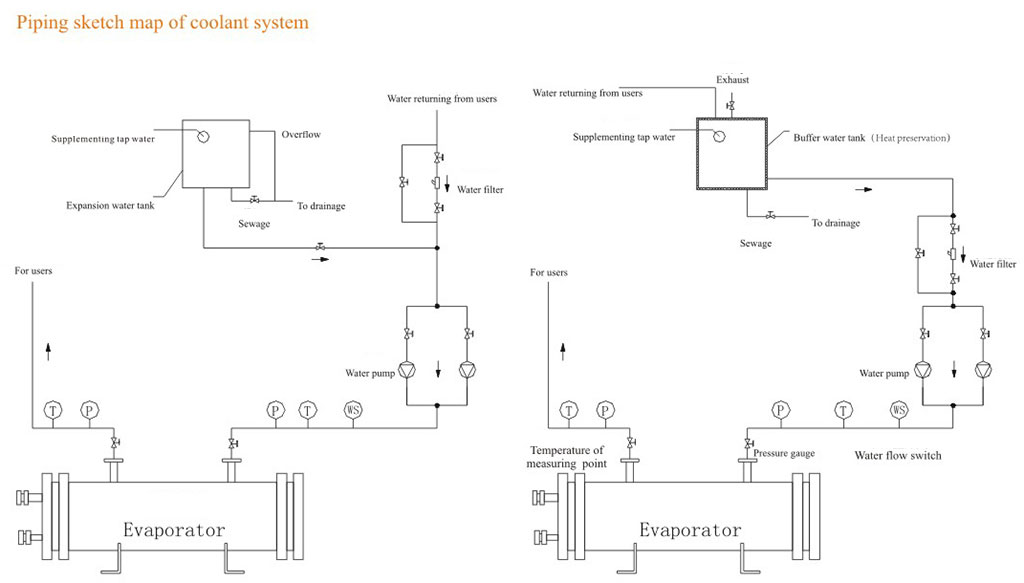

1 .Buffer tank shall be installed in the pump suction inlet; expansion tank shall be installed at the highest point of the system; please consult the company for switch of pressure expansion installation; release valve shall be installed in the lowest point of the water system, so that water can be drained off in winter when it's not in use. One water pump is for use and one for standby.

2.Release valve shall be installed at the top of the inverted "U" bend and the highest point of the pipe of refrigerant water system.

3.The company provides the design fbr pump frequency operation, or single constant frequency/double-conversion energy-saving operation of multi-unit water system.

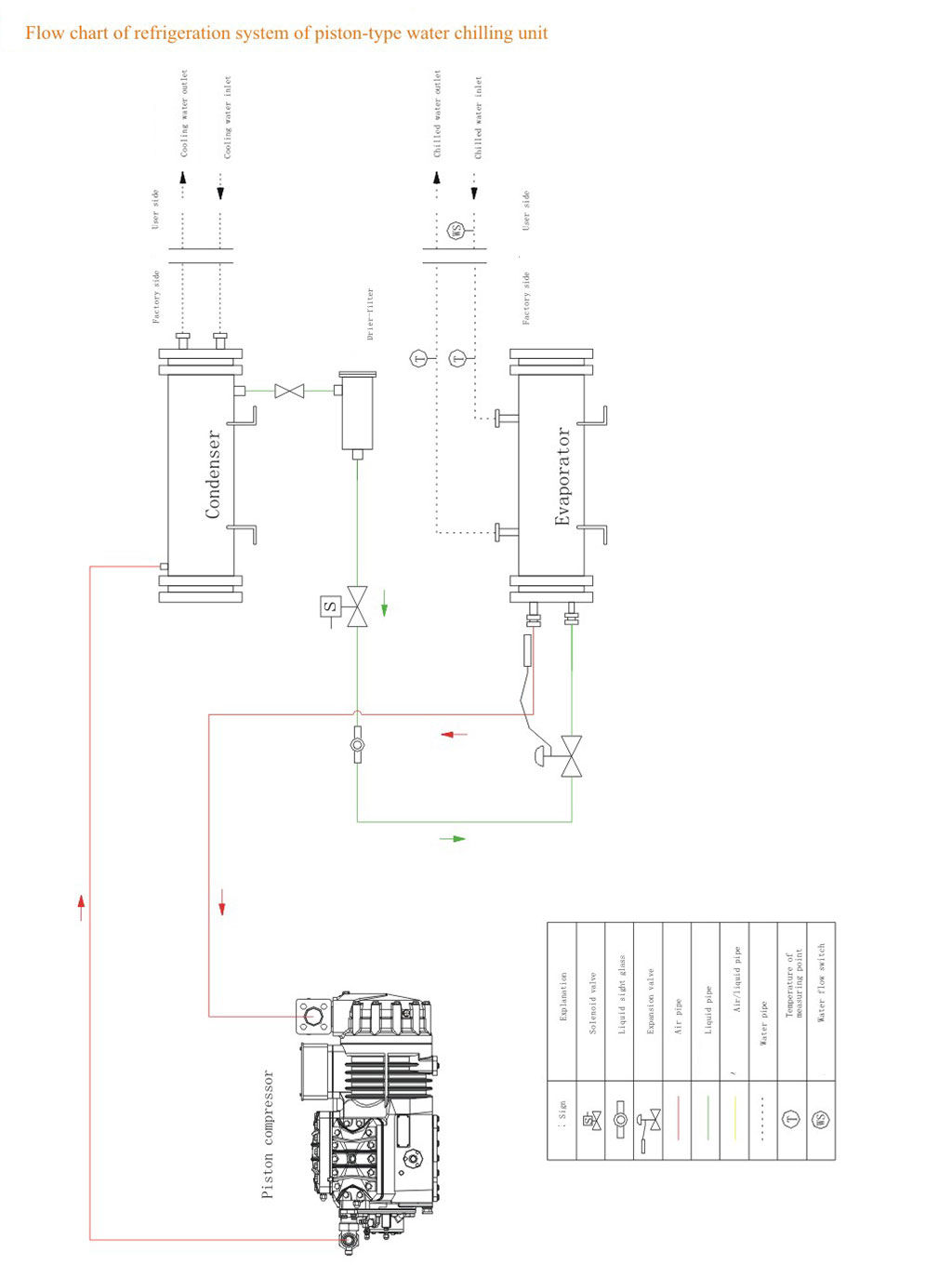

—Description:

♦This diagram is fbr reference only

♦Expansion tank or buffer tank are required to be installed in the refrigerant water system. Different requirements of users or usage modes will lead to difference in piping, and please contact the company at the condition of no professional design.

♦During initial operation of equipment, the cut-off valve of inlet and outlet equipment should be shut oft; and the by-pass cut-off valve should be opened for pipeline flushing, so as to avoid the entering of welding slag, sand and other foreign matter into the heat exchanger and affect its efficiency or damage the equipment.

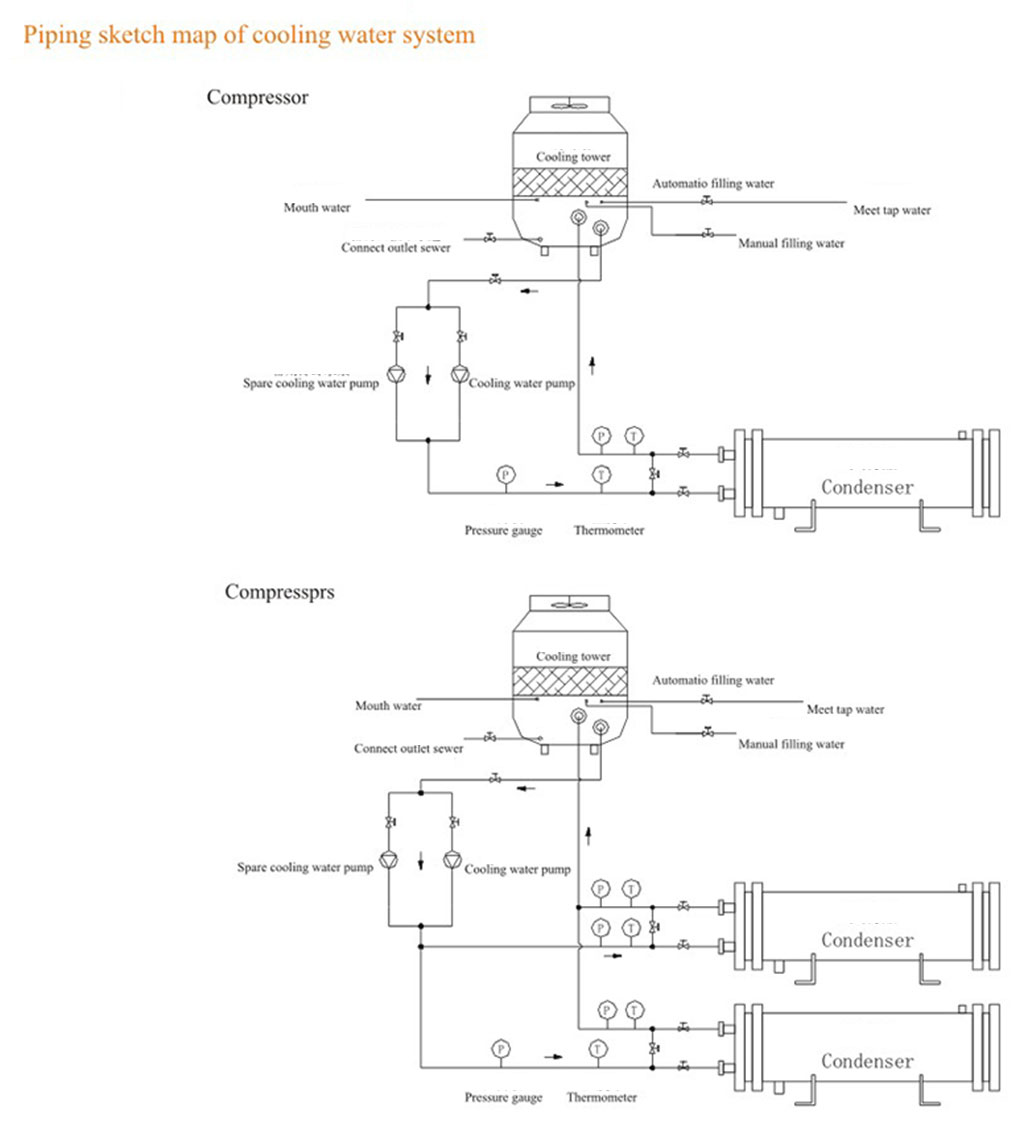

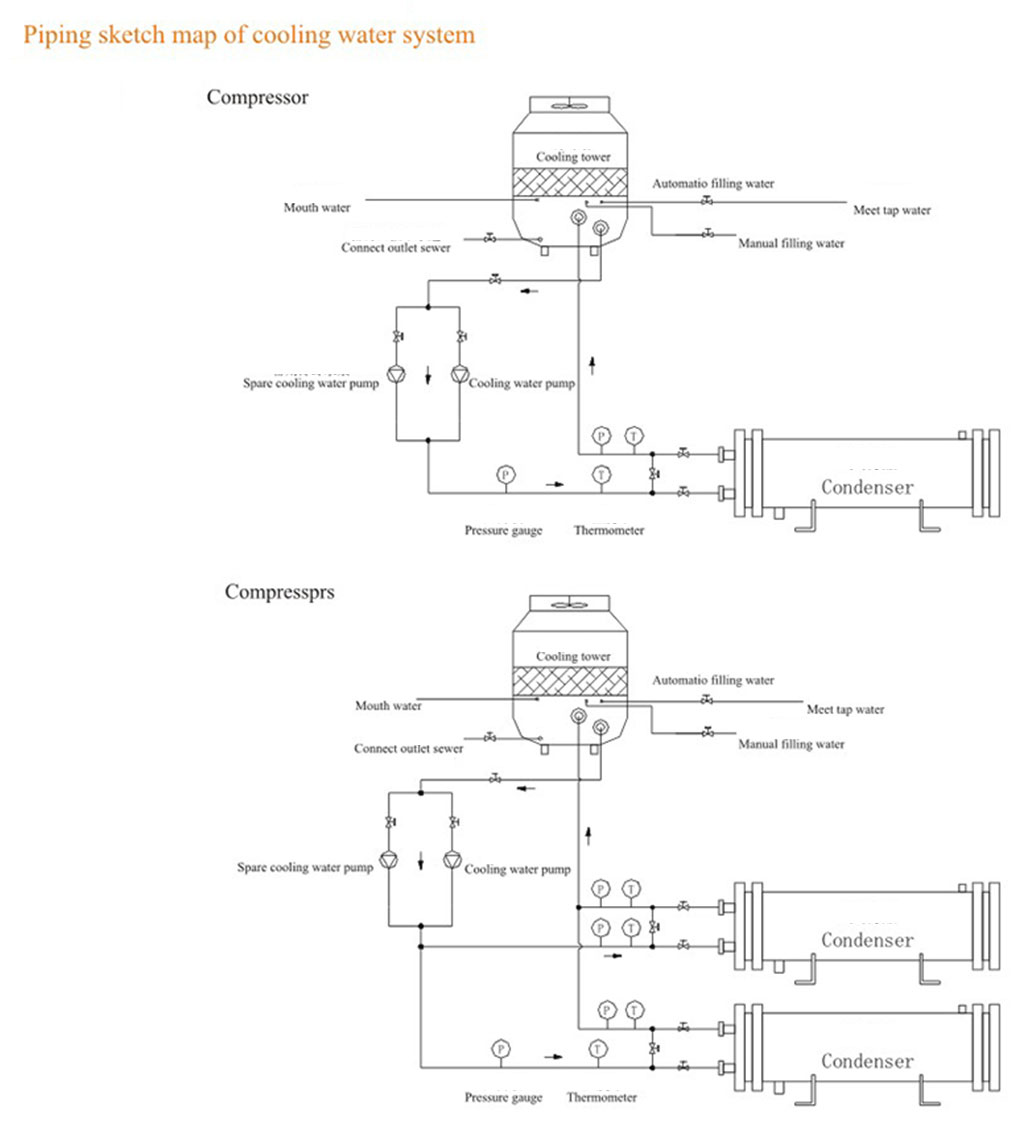

1.The outlet pipe of the cooling tower should be higher than the highest point of the suction pipe of cooling water pump.

2.Release valve shall be installed in the lowest point of the water system, so that water can be drained off in winter when it's not in use. One water pump is fbr use and one fbr standby is recommended.

3.The company can provide the design fbr pump frequency conversion scheme fbr energy saving operation.

—Description:

♦This diagram is fbr reference only

♦ During initial operation of equipment, the cut-off valve of inlet and outlet equipment should be shut off^ and the by-pass cut-off valve should be opened fbr pipeline flushing, so as to avoid the entering of welding slag, sand and other foreign matter into the heat exchanger and affect its efficiency or damage the equipment.

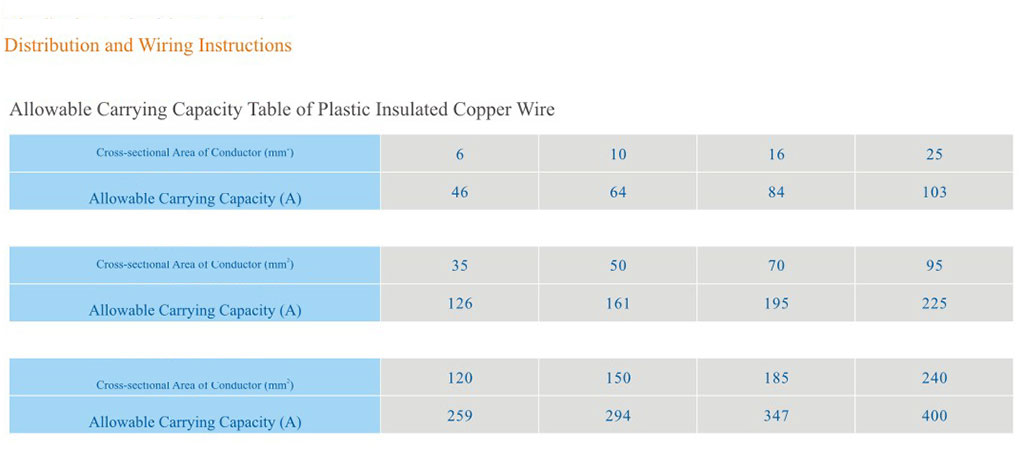

-♦Note:

♦Allowable carrying capacity of the above wires is open wire laying copper wire, allowing long-term operating temperature of 70°C, ambient temperature of 35°C, quoted from GB/T 16895.15.

♦The above wiring specifications are for reference only. Specific conditions should be decided by the professional electrical design department according to actual needs, but in principle, they should be no less than the above specifications, or else they will cause failure of compressor in starting up due to large line loss.

♦During the operation of the unit, power supply voltage must be stable. Taking into account the voltage drop factors, operating voltage of the unit's long-term operation shall remain within ±5% of the rated value, and instantaneous operation shall remain within ±10% of the rated value.

Voltage between phases shall not exceed ±2% of the rated value, and current difference between maximum and minimum phases must be less than 3% of the average current. Voltage frequency should be maintained within 土 2% of the rated value.

♦Construction of wiring between the power supply and the unit shall be in strict accordance with electrical regulations and standards, and provided with good insulation. After wiring, a 500V megger shall be provided to determine the insulation between the terminals of electrical accessories and the unit, and its insulation resistance shall be at least 5MQ.

♦The wiring should adopt the three-phase five-wire system, and shall only use copper wires.

♦The unit grounding must comply with the relevant local and national provisions.

♦The user side of the unit power inlet line shall be equipped with air circuit breaker of proper volume.

Standard scope of supply:

Manufactured products are qualified products, and a small amount of refrigerant has been filled in the system.

♦According to user requirements, the company can provide: refrigeration oil, filter element of molecular sieves, refrigerants and other spare parts.

Related Products

- WhatsApp 0571-88086095

- Message

- Hotline 0571-88086095

- Back to top

Hotline:0571-88086095

After sales:0571-88133312

Accessories sales:0571-88121275

E-mail:13346197521@163.com

Online Message

Zhejiang Commercial Machinery Factory Co., Ltd. 浙ICP备05030721号-1 Powered by www.300.cn hangzhou